Our Cleaning Validation Services provide end-to-end scientific and regulatory support to demonstrate the effectiveness of cleaning processes and ensure compliance with global GMP requirements. We specialize in consultancy, analytical method development, validation, and routine analysis, offering comprehensive programs designed to verify that residues of active ingredients, cleaning agents, and other contaminants are effectively removed from manufacturing equipment.

We support clients across pharmaceutical, nutraceutical, and chemical manufacturing environments, ensuring that cleaning validation strategies are practical, defensible, and aligned with both product risk and regulatory expectations.

Comprehensive Cleaning Validation Capabilities Include:

-

Consultancy & Strategy Development

-

Establishment of risk-based cleaning validation programs

-

Assessment of equipment design, product groupings, and worst-case scenarios

-

Determination of acceptable residue limits (MACO/PDE calculations)

-

Preparation and review of cleaning validation master plans and protocols

-

-

Analytical Method Development & Validation

-

Development of specific and sensitive methods for detection of residues and cleaning agents

-

Techniques include HPLC, TOC, conductivity, UV-Vis, and other validated approaches

-

Validation performed per ICH Q2(R2) and relevant GMP guidelines

-

Assurance of method robustness, linearity, accuracy, and recovery

-

-

Residue Analysis & Routine Testing

-

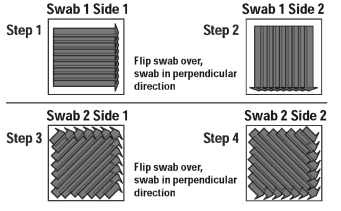

Swab and rinse sample analysis for product and detergent residues

-

Quantitative determination of trace contaminants to verify cleaning effectiveness

-

Support for ongoing verification programs and periodic revalidation

-

-

Documentation & Regulatory Support

-

Preparation of validation protocols, reports, and data packages suitable for audit or submission

-

Alignment with FDA, EMA, PIC/S, and other global GMP requirements

-

Assistance with responses to regulatory observations and remediation planning

-